KeraTwin K18

KeraTwin K18

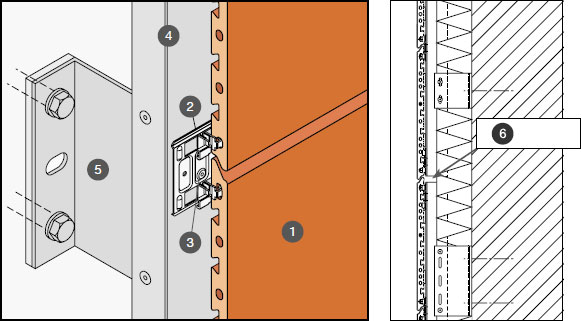

The facade panels KeraTwin® K18 have dovetail grooves on the back into which at least four adapters per panel are pushed (symmetrical arrangement). The position of the adapters in the panel depends on the static requirements. The KeraTwin® K18 panel is hung in horizontally installed supporting rails by means of these adapters. The stainless steel springs inserted in the adapters serve for the nonrigid installation. A spacer put in the grooves, which is adjusted to the joint width, secures the position of the panels.

KeraTwin® K18 – with adapter fastening

- Facade panel KeraTwin® K18

- Complete adapter, article 596

- Horizontal supporting rail, article 597

- Vertical bearing profile (basic substructure)

- Wall bracket (basic substructure)

- Pay attention to profile butt joint! A profile butt joint of the vertical bearing profiles behind a panel is not allowed! See standard technical detail drawings.

Essential system advantages

- Rapid panel installation with well thought-out system components

- The low panel weight of 32 kg/m2 facilitates transport and handling and also permits the use in case of a statically demanding building structure

- Installation in semi-bond or irregular bond is possible

- Great design scope thanks to a wide variety of sizes with a panel thickness of 18 mm

.

.

KeraTwin® K18 – with clamp fastening

System description

The facade panels KeraTwin® K18 are fixed laterally in the channels of the facade panels by means of the stainless steel clamps of system KT. To prevent clattering and constraining forces in the case of alter nating wind loads, the facade panels are installed on the substructure in a nonrigid way by using foamed pieces or alternatively with polyurethane.

- Facade panel KeraTwin® K18

- Twin-clamp KT, article 360

- Stainless steel blind rivet, article 675

- Vertical bearing profile (basic substructure)

- Wall bracket (basic substructure)

- Pay attention to profile butt joint! A profile butt joint of the vertical bearing profiles behind a panel is not allowed! See standard technical detail drawings.

Essential system advantages

- Rapid and proven panel installation with well thought-out system components

- The low panel weight of 32 kg/m² facilitates transport and handling and also permits the use in case of a statically demanding building structure

- Horizontal and vertical installation is possible

- Panel installation on ceilings is possible

- Great design scope thanks to a wide variety of sizes

| Standard heights: (grid size/work size) |

20 cm / 204 mm, 25 cm / 254 mm, 30 cm / 304 mm, 35 cm / 354 mm, 40 cm / 404 mm Other heights available on request. |

| Lengths (work size): | 392 up to 1,350 mm (in 1 mm steps) |

| Thickness: | 18 mm |

| Weight per unit area: | 32 kg/m2 |

| Colours/surfaces: | For the colour chart, see pages colour chart For surfaces and cross-section variations, see pages surfaces |